Once the dory was stowed on deck, the ship then drew alongside the seine boat, which was secured to a towing boom on the starboard side of the ship. The side of the seine opposite the formerly open end had a rectangular extension, known as the bail, which was marked by red and white painted corks. The section was hauled on board the ship and secured to a board fastened to the bulwark on the starboard side as the men on the seine boat hauled the seine onboard that boat to progressively shrink the size of the seine as the catch was brought on board the ship for processing.

The first picture shows the seine boat alongside the mother ship being towed with the boom, the seine between the two vessels. The rectangular part of the seine has been hauled onto the larger ship and fastened into notches on a board along the bulwarks on that side, as the crew of the seine boat works to pull the netting onto the seine boat and reduce the size of the seine enabling the dipper to transfer the fish to the deck of the Latham.

Sometimes, when the seine was being deployed, the captain conned the seine boat, with the cook at the helm of the ship the only man on board, but the captain returned to the ship once the seine was closed.

The seine was emptied using a large dip net, suspended from a dory tackle on the main cross tree, starboard side, and guided by a second crewman using its long handle. The mackerel were dipped out and the net emptied onto the deck in a mass of flopping fish and flying scales.

Once on deck, the mackerel were processed by being cleaned and salted down into barrels. The Keeler first opened the fish along the backbone and passed the fish to the Gibber, who removed the entrails before depositing the fish into a barrel of brine. The Keeler and Gibber generally worked over open boxes placed on barrels to make a working table, or placed the boxes onto the cabin roof. The boxes held the fish to be processed. A crewman shoveled or netted fish into the box of the keeler, who passed the opened fish to the box of the gibber. Sometimes salt was added to the gibber’s box or more often added when, after removal of entrails, the gibber put the fish into the barrel.

Once a barrel was full of fish, it was passed to the cooper, who placed a lid on the barrel and fastened it by driving the barrel hoops down to tighten the staves. The barrels usually had hoops made of saplings with ends twisted under and secured by a tap. There was also often a bung to permit opening the bunghole to add salt or brine.

Full barrels are standing around the deck, awaiting stowage below deck, along with some empties awaiting fish.

Filled barrels accumulated on deck and most were later transferred to the hold for the speedy voyage back home, but if the catch was large, the ship would return with barrels secured on deck. Depending on the size of the vessel and the size of the catch, hundreds to over a thousand barrels might be transported back. If a vessel was particularly fortunate, and the mackerel catch exceeded its capacity, the captain might fly a signal for other ships to lay alongside to share the catch, on shares, of course.

This model shows the ship with mainsail lowered and the main topsail clewed up. The “jumbo” jib is also furled. Foresail, foretopsail, inner and outer jibs, and the staysail are deployed. This configuration was suggested by several contemporary photographs of working vessels while processing the catch. I suspect the sails might not have been sheeted home but allowed to draw only partially, but ready for immediate use in the coming sprint back to the market.

In the diorama, the seine boat is towed on the starboard (leeward) boom as the seine crew continues to haul the net into the boat. The seine boat has a small log pump in the after cuddy so the master of the boat can pump/bail out the water taken on with the net. The boat master also uses the steering oar to maintain working distance from the ship. The other oars are stowed in a metal rack on the side of the boat, out of the way as the crew hauls in the net.

Aft, on the portside, opposite the side of the seine, two crew empty a barrel of entrails, attracting a couple of sharks. Early reports from the seine fisheries described dogfish attaching the mackerel in the nets tearing holes in the netting and allowing the mackerel to escape. Later, use of heavier cordage for the nets prevented the problem. I thought the crew might scatter chum away from the net to attract shark elsewhere. If you look closely at the lower picture, you might be able to see one of the sharks.

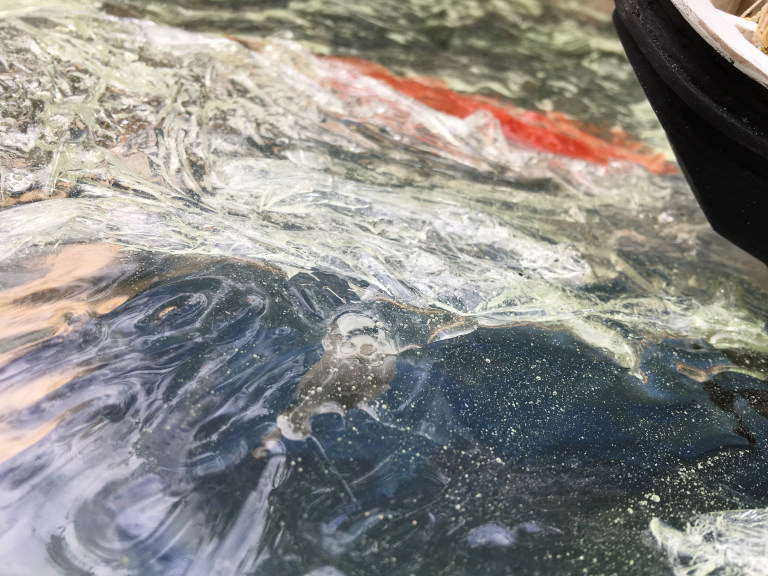

The case for the model is made of oak with acrylic glazing. The case separates at the waterline and the lower portion is also glazed with acrylic sheet with layers of tinted epoxy resin applied to the inside of the sides for a water effect and to the top surface of the top of the lower case to model the sea. This sheet is cut out for the ship and the seine boat, which are cemented in place. The bottom of the lower case is plywood, painted a dark green with flat acrylic paint, which is then mottled with blues and black. The light entering the sides of the case is blued by the tinted epoxy on the sides so the color of the bottom, the deeper water, is a satisfactory teal color, modified by the light patterns through the distortion of the epoxy patterns.

The water surface is multiple layers of epoxy resin. I used a rapid setting resin and stirred it vigorously to entrain some air bubbles, added some tints, and stirred the surface as the resin cured to create wave patterns. The waves along the hull and the wakes were modeled using clear plastic wrap in the resin.

Here are some additional detail shots of the vessel. I did a little bit of weathering of the paint, and added some dirt and rust to make it look like a working boat.